Just one firm makes these machines, Dutch agency ASML, and the second-generation EUV machines are already accessible. Often known as Excessive-NA, these $400 million machines assist foundries construct built-in circuits utilizing a 7nm course of node and decrease. It clearly takes large sums of cash to open a foundry to make chips and these prices are handed on to smartphone producers who then move them on to us.

Progressive EUV devised by Okinawa Institute of Science and Know-how generally is a recreation changer in chip manufacturing

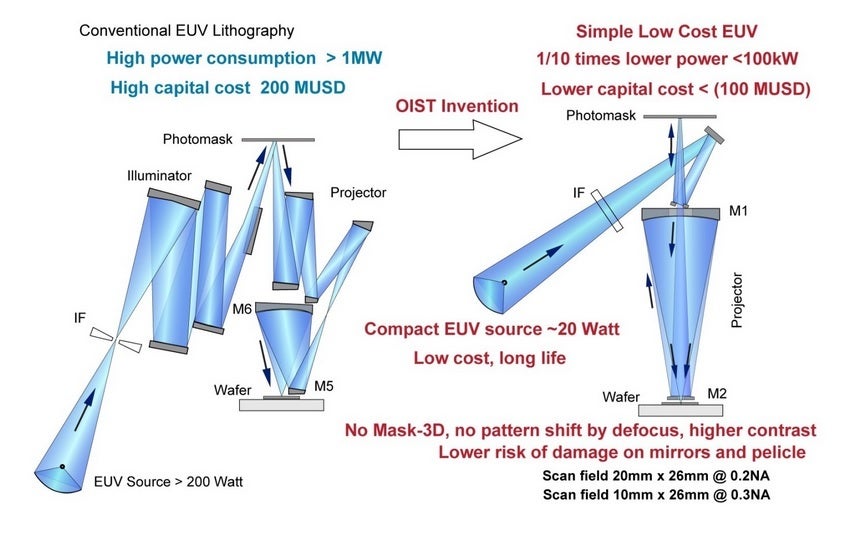

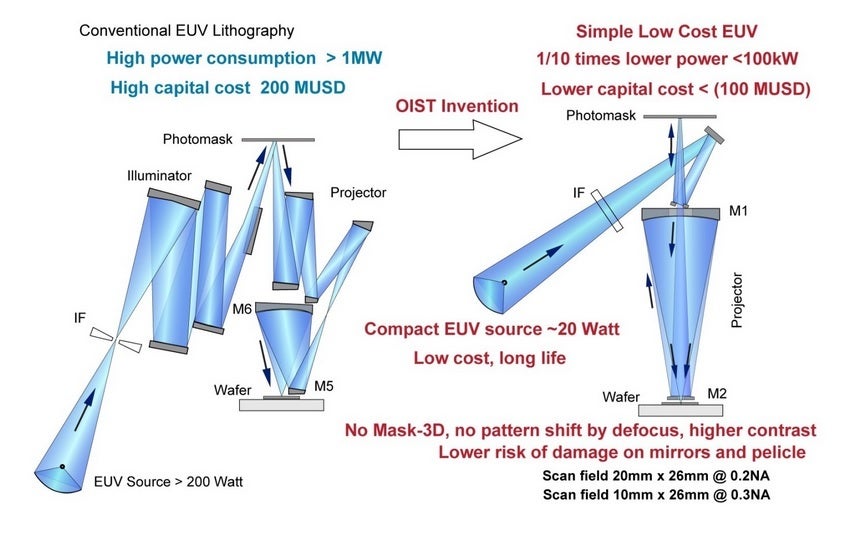

At left, the normal EUV, and at proper, the decrease price mannequin from OIST. | Picture credit-OIST

The OIST report mentions that the brand new applied sciences for the EUV machine take care of a few points beforehand thought-about insurmountable. The brand new EUV machine employs an optical projection system that requires the usage of solely two mirrors. The second innovation permits mild from the EUV to be directed onto logic patterns on a flat mirror with out blocking the trail of the sunshine. Professor Shintake says, “This invention is a breakthrough know-how that may virtually fully clear up these little-known issues.”

As a result of EUV rays have extraordinarily quick wavelengths, they can’t journey by way of clear lenses. As a substitute, in EUV machines, the sunshine is directed by utilizing crescent-shaped mirrors that direct the sunshine in a zig-zag sample. As a result of the sunshine deviates from the central axis, it reduces the general efficiency of the machine.

Shintake found that by aligning two axisymmetric mirrors with tiny middle holes in a straight line, superior outcomes may be achieved. The place conventional EUV machines use over 1MW of energy and have capital prices of over $200 million, the progressive low-cost machines use lower than 100kW of energy, and capital prices are underneath $100 million. As well as, typical EUV machines require a supply of sunshine that measures over 200W whereas the low price unit requires a 20W mild supply.

Decreasing the variety of mirrors from 10 to 4 may stop the machine from dropping an excessive amount of power

EUV power weakens by 40% with each bounce of sunshine off of a reflective mirror. The report says that by limiting the variety of mirrors used to 4 from the EUV supply to the wafer, “greater than 10% of the power makes it by way of, that means that even a small EUV supply with an output of some tens of watts can work simply as successfully. This will result in a major discount in energy utilization.” With the brand new two-mirror projection methodology changing the six used for projection with a traditional EUV, much less power is wasted.

Professor Shintake states, “The worldwide EUV lithography market is predicted to develop from 8.9 billion USD in 2024 to 17.4 billion USD in 2030, with a median annual progress price of roughly 12%. This patent has the potential to generate great financial advantages.”