The world’s two prime foundries are, so as, TSMC and Samsung Foundry. Each began working excessive ultraviolet (EUV) lithography into their chip manufacturing again in 2019 which set the stage for chips to be made utilizing nodes beneath 7nm. You see, lithography machines etch circuitry patterns onto silicon wafers to assist construct semiconductors. The decrease the method node, the smaller the chip’s characteristic set together with transistors.

Smaller transistors imply that extra of them can match inside a die; with tens of billions of transistors inside fashionable chipsets (for instance, the 3nm A17 Professional sports activities 20 billion transistors in every chip!) these circuitry patterns have to be extraordinarily skinny. And that’s the place the EUV lithography machine comes into play. It’s constructed by only one firm in all the world, Dutch agency ASML. Understand that the upper a chip’s transistor rely, the extra highly effective and/or energy-efficient that chip is.

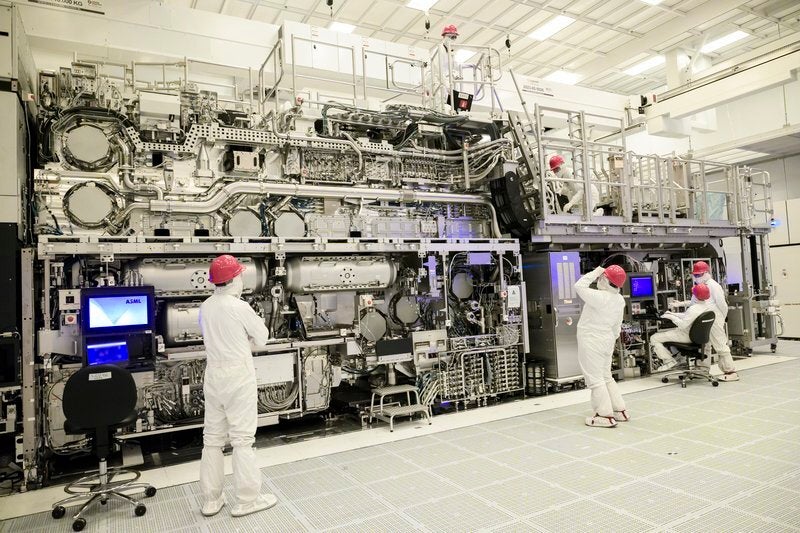

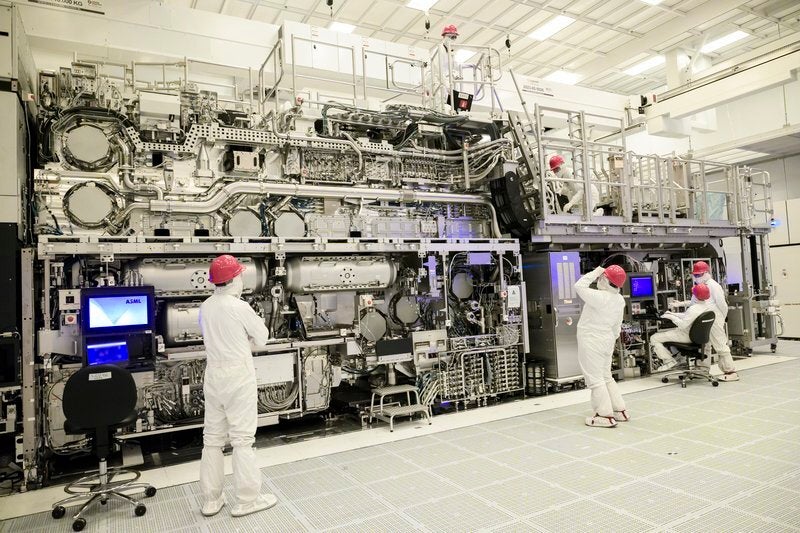

A high-NA EUV lithography machine being assembled in Oregon. | Picture credit-Intel

Whereas the first-gen EUV helped foundries crack the 7nm node, the high-NA EUV machines will take chip-making to the 1nm course of node and decrease. ASML says that the numerical aperture, which is what the “NA” abbreviation stands for in high-NA, measures the flexibility of the optical system to gather and focus mild. The upper NA of .55 on the next-gen machines is what helps the brand new gear carry out higher than the first-gen machines.

“Intel expects to make use of each 0.33NA EUV and 0.55NA EUV alongside different lithography processes in creating and manufacturing superior chips, beginning with product proof factors on Intel 18A in 2025 [1.8nm] and persevering with into manufacturing of Intel 14A [1.4nm]. Intel’s method will optimize superior course of know-how for price and efficiency.

Nonetheless, Intel continues to be coping with low yields, purple ink, and a tumbling inventory value which acquired the corporate’s shares booted from the U.S. inventory market’s 30-stock Dow Industrial bellwether the place it was changed by Nvidia. Issues are going so poorly for Intel that it’s outsourcing its manufacturing all the way down to 3nm to TSMC.